AIR BRAKE Interactive Classroom Edition (ABI-CE)

For more information and/or to discuss with one of our expert teaching resource developers, please contact:

Bryan Duross

TECHNICAL TRAINING SERVICES

Telephone: 519-621-0708

E-Mail: bduross@sentex.net

AIR BRAKE Interactive Classroom Edition (ABI-CE) is an air brake training and teaching resource designed for air brake service instructors teaching entry to intermediate level air brake students and service technicians. It is also well suited for advanced air brake training for drivers. ABI-CE is a complete, presentation-ready, training package that has been carefully structured to deliver a progressive and effective learning experience.

The AIR BRAKE Interactive CE package consists of a highly detailed, full color, 12-module, 350 page Instructor’s Reference and Presentation Guide supported by a state-of-the-art CD-ROM multimedia presentation.

The Instructor’s Reference and Presentation Guide

The Instructor’s Reference and Presentation Guide provides presenters with a wealth of detailed reference information and a point-by-point guide for presenting their program. Combined with the program’s powerful multimedia support animations and visuals, you are assured of a thorough, accurate and consistent presentation by every instructor, every time!

Available Student Workbook

This high quality, full color, 110-page Student Workbook is the ideal support publication for your AIR BRAKE Interactive Classroom presentations. Exactly paralleling the structure and content of your classroom presentation this book will provide your students with a valuable and durable technical reference long after the completion of their air brake studies. Call or e-mail us for details and pricing.

The Multimedia Presentation

The multimedia presentation contains 44 voice narrated technical/mechanical animations and over 75 additional technical visuals detailing the operation of a typical modern heavy vehicle air brake system. A few examples of these visuals are illustrated to the left. This is a visual learning experience that your students will understand and remember.

Presenting the Program

You can present the entire ABI-CE program (approximately 16 classroom hours) or pick and choose what subject matter you wish to present and what individual visual elements you wish to employ. It’s up to you.

AIR BRAKE Interactive IS NOT a re-assembly of age-old air brake training material that has been around for decades. AIR BRAKE Interactive CE employs ALL NEW and ORIGINAL MATERIAL. Its content, structure, system diagrams, technical animations and illustrations have been carefully designed and created to reflect current air brake technology. AIR BRAKE Interactive CE will provide your students with the most thorough air brake education possible. It is the most comprehensive and effective air brake teaching resource available today.

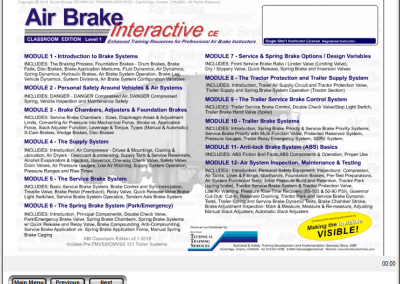

ABI-CE Content

MODULE 1 – Introduction to Brake Systems

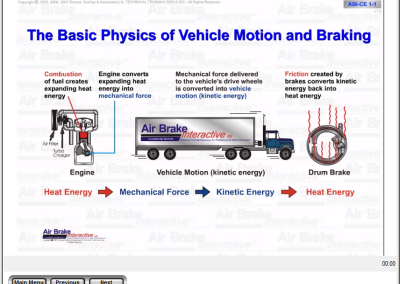

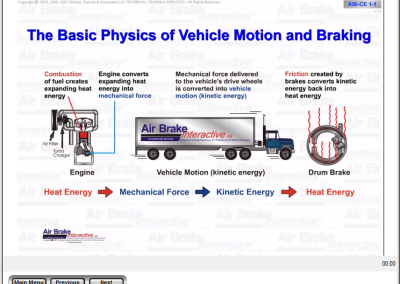

• Basic Physics of Vehicle Motion and Braking (How Brakes Slow and Stop a Vehicle)

• Brake Basics – Foundation Brake Types

• Drum Brakes – Principal Components and Basic Operation

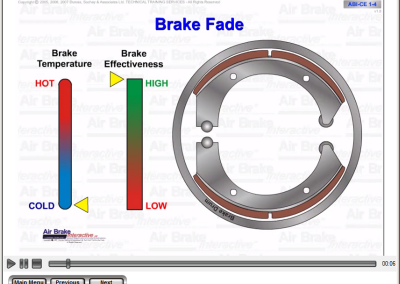

• Brake Fade (A Drum Brake Phenomenon)

• Disc Brakes – Principal Components and Basic Operation

• How Brakes are Applied – The Mediums Used to Activate Brake Systems

• Basic Fluid Dynamics (Hydraulics)

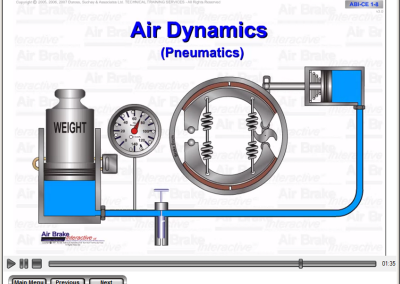

• Basic Air Dynamics (Pneumatics)

• Spring Dynamics

• Hydraulic Brakes

• Air Brakes – Basic Operation

• Brake Lag

• Brake Lag and Stopping Distance

• Vehicle Speed, Weight and Stopping Distances

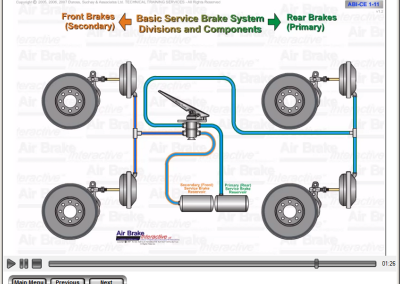

• Air Brake System Divisions

• Air Brake System Configuration Variables

MODULE 2 – Personal Safety Around Vehicles and Air Brake Systems

• Compressed Air, DANGER

• Compressed Spring, DANGER

• Vehicle Inspection and Maintenance Safety

MODULE 3 – Service Brake Chambers, Slack Adjusters and Foundation Brakes (Wheel Brakes)

• Service Brake Chambers – How they work, Component Identification and Operation

• Brake Chamber Sizes and Effective Diaphragm Areas

• Converting Air Pressure into Mechanical Force (Area X Pressure = FORCE)

• Brake Chamber Size, Markings, Outside Diameter (OD) and Adjustment Limits

• Brake Chamber Stroke vs. Application Force

• Slack Adjuster – Basic Function, Leverage & Torque

• Slack Adjuster Types (Manual & Automatic)

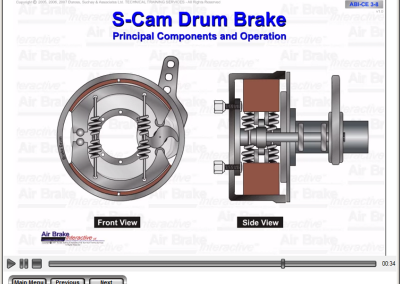

• S-Cam Brake – Component Identification and Operation

• Wedge Brake – Component Identification and Operation

• Disc Brake – Component Identification and Operation

MODULE 4 – The Supply System

• Supply System – Introduction and Overview

• Air Compressor Components – Drives and Mountings

• Air Compressor Component Identification and Operation

• Air Compressor Cooling and Lubrication

• Optional Compressor Induction System (Utilizing Turbo-Charger Boost Pressure)

• Air Dryer Types

• Desiccant Air Dryer – Component Identification and Operation

• Aftercooler Condensing Air Dryer

• Supply Tank & Service Reservoirs

• Alcohol Evaporators & Injectors

• Governor

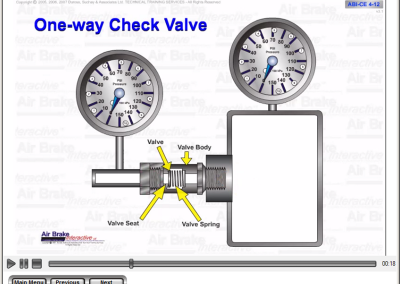

• One-way Check Valve

• Safety Valve (Over-Pressure Relief Valve)

• Drain Valves (Manual and Automatic)

• Air Pressure Gauges

• Low Air Pressure Warning Devices

• Supply System Operation

• Pressure Ranges and Rise Times

MODULE 5 – The Service Brake System

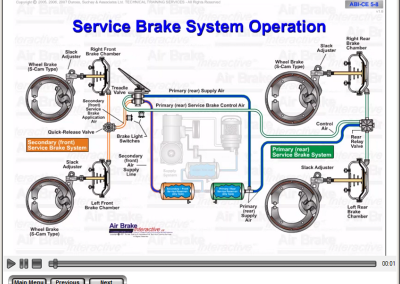

• Basic Service Brake System – Component Identification

• Brake Control and Synchronization (Quick Release and Relay Valves)

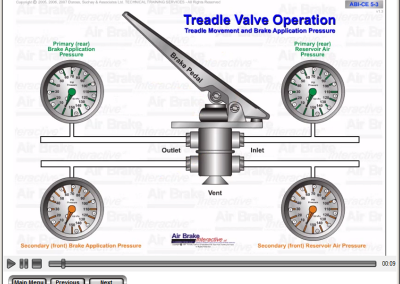

• Treadle Valve – Component Identification and Operation

• Brake Pedal Feel (Feedback)

• Primary (Rear) Relay Valve

• Secondary (Front) Quick Release Valve

• Brake Light Switches

• Service Brake System Operation

• Tandem Axle – Service Brake System

MODULE 6 – The Spring Brake System (Park / Emergency Brakes)

• Spring Brake System – Introduction and Principal Components

• Double Check Valve Design and Operation (Shuttle-type)

• Park / Emergency Brake Control Valve Operation

• Spring Brake Chamber – Component Identification and Operation

• Spring Brake System (Basic) with Quick Release Valve

• Spring Brake System with Relay Valve

• Brake Compounding

• Basic Anti-Compounding Circuit (with Standard Spring Brake Relay)

• Anti-Compounding Circuit (with Anti-Compounding Spring Brake Relay)

• Service Brake Application Force vs. Spring Brake Application Force

• Manual Spring Brake Caging

MODULE 7 – Service and Spring Brake System Options and Design Variables

• Secondary (Front) Service Brake Ratio / Limiter Valve (Limiting Valve)

• Dry / Slippery Valve

• Spring Brake System with Quick Release and Spring Brake Valves (Inversion Valves)

MODULE 8 – The Tractor Protection and Trailer Supply System

• Tractor Protection and Trailer Supply System – Introduction

• Trailer Air Supply Circuit – Component Identification

• Trailer Air Supply Valve – Basic Function

• Combination Tractor Park and Trailer Air Supply Valves

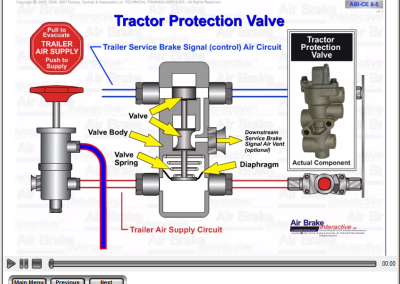

• Tractor Protection Valve

• Trailer Supply and Spring Brake System Operation (Tractor Section)

MODULE 9 – The Trailer Service Brake Control System

• Trailer Service Brake Control System Components

• Double Check Valve / Stop Light Switch Function

• Trailer Service Brake Control System Operation

• Trailer Brake Hand Valve (Spike) – Introduction, Warning

• Trailer Brake Hand Valve (Spike) – Component Identification and Operation

MODULE 10 – Trailer Brake Systems

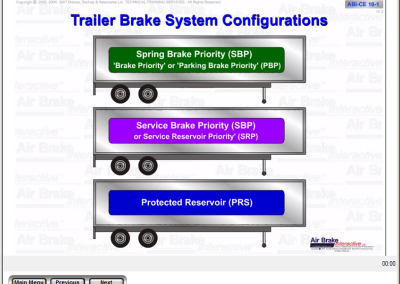

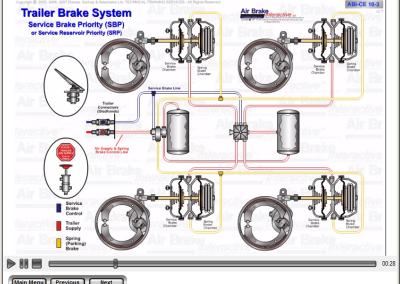

• Trailer Brake Systems – Introduction

• Spring Brake Priority System Component Identification & Operation

• Service Brake Priority System Component Identification & Operation

• Service Brake Priority (with Multi-Function Valve)

• Protected Reservoir System

• Trailer Systems Summary

• What Your Air Pressure Gauges Tell You and DON’T Tell You

• Trailer Relay Emergency Systems (Introduction)

• Trailer Relay Emergency System (Pre-121 with Service Brake Chambers Only)

• Trailer Relay Emergency System (Pre-121 with Service & Spring Brake Chambers

• Trailer Relay Emergency System (SERV System w/ Service & Spring Brake Chambers)

MODULE 11 – Anti-lock Brake System (ABS) Basics

• ABS Fiction and Facts

• ABS Components and Operation

• ABS – Proper Use

MODULE 12 – Air Brake System Inspection, Maintenance and Testing

Visual Inspections:

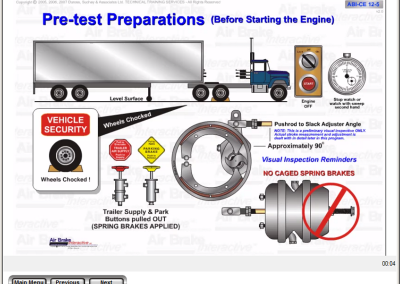

• Introduction and Personal Safety Equipment (In Pre-Engine-Start Procedures)

• Compressor Inspection

• Air Tanks, Lines and Fittings, Gladhands

• Foundation Brakes

• Pre-Test Preparations (Before Starting the Vehicle)

Air System Functional Tests:

• Initial Pressure Build and Retention

• Tractor Park (spring brake) System

• Tractor Service Brake System (and Tractor Protection Valve)

• Low Air Warning System

• Pressure Rise-Time Recovery (85 – 100 PSI) and Governor Cut-Out

• Pressure Rise-Time Recovery (50 – 90 PSI) and Governor Cut-Out

• Compressor Cut-in

• Supply and Service Reservoir Draining

• Tractor Park and Service Brake Dynamic Tests

• Trailer Supply, Spring and Service Brakes

• Trailer Spring and Service Brake Dynamic Tests

• Brake Chamber Stroke (A Crucially Important Adjustment)

• Brake Stroke Inspection and Adjustment (Before Checking Brake Chamber Stroke)

Brake Adjustment Inspection:

• Brake Stroke Inspection – Introduction, Test Preparations and Equipment

• Brake Stroke – Mark & Measure

• Brake Stroke – Measure & Re-measure

• Brake Stroke Adjustment – Introduction, Brake Component Wear & Brake Stroke

• Adjusting Manual Slack Adjusters (adjustment procedures)

• Automatic Slack Adjusters (12-Pack to Go – Initiating the Auto Adjust Process)

• REVIEW – Basic Spring and Service Brake System Function